The Ultimate Guide for Engineers, Buyers & Founders — From Basics to Deep Insights

📌 Introduction

Whether you’re building a prototype, scaling production, or switching vendors, choosing the right CNC machining service can make or break your timeline, cost, and product performance.

This is not about just finding “a supplier.”

It’s about finding the right precision partner.

In this guide, you’ll discover how to evaluate a CNC supplier like a pro — not just on price, but on capability, reliability, and long-term performance. If you’ve been in engineering for 10 years, you’ll still find new strategies here.

Why This Matters

A great CNC machining partner:

Cuts your cost without cutting corners

Delivers parts that pass QA on the first try

Solves problems with your drawing, not creates them

Helps scale from 10 pcs to 10,000 without stress

A poor one?

Wastes your time

Delays your projects

Destroys your trust

How to Choose the Right CNC Machining Service – Step by Step

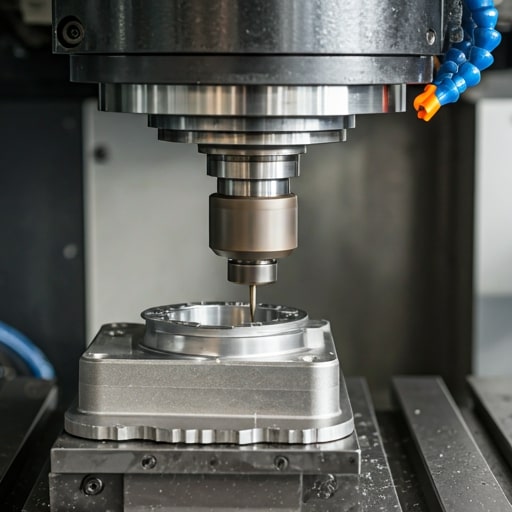

1. Match Their Capabilities to Your Component Type

Not all CNC shops are equal.

| If you need… | Look for… |

|---|---|

| Shafts, bushings, pins | CNC Turning (2–3 axis lathes) |

| Complex profiles, brackets | VMC (3-axis or 4-axis milling) |

| 5-sided, deep pocket parts | 5-axis CNC |

| Mirror surface or tight tolerance | Lapping/grinding + CMM/QC tools |

| Aerospace/Medical/Defence | Certifications: ISO 13485, AS9100 |

Ask what machines they have: brands (e.g., HAAS, DMG Mori, Jyoti), year of make, tool management system, CAM software.

2. Look Beyond Just Price – Ask How They Calculate It

Any shop can give a price — but only the right one explains how.

🔍 Ask:

How much time is estimated for tool path?

What’s the material stock removal rate?

How many setups are needed?

What about surface finish prep?

Is post-processing included in quote?

If they reply instantly with a round figure — run.

If they explain honestly and technically — stay.

3. Review Sample Parts, Not Just Photos

A real CNC partner has nothing to hide.

🛠 Ask for:

Photos of parts made for similar industries

Close-up shots of threads, corner radii, surface finish

Sample part with tolerance report (micron-level if needed)

💡 Tip: Ask them to send a raw unpolished part — that’s how you judge actual machining quality.

4. Audit Their Inspection Capabilities

You’re not just buying machining. You’re buying consistency.

Your CNC partner should have:

Vernier, micrometer, height gauge (basic)

Bore gauge, thread gauge, slip gauges (for GD&T)

CMM or profile projector (for precision)

SOP for in-process + final inspection

🚫 If their QC process is “we just check by hand” — walk away.

5. Understand Their Material Control & Traceability

Great components start with great raw material.

Your supplier must:

Maintain material inward register with heat numbers

Give material test certificates (MTCs) when needed

Mark rejected raw stock and store separately

Use FIFO (First In, First Out) stock rotation

📦 Pro tip: Ask how they store aluminum vs stainless steel — mixed storage leads to surface damage & oxidation.

6. Ask About Lead Time, Not Just Delivery Date

There’s a big difference between:

“Delivery in 8 days”

vs.

“2 days material purchase, 1 day programming, 2 days machining, 2 days finishing, 1 day QC & packing”

🛠 A professional supplier breaks down your lead time honestly.

They also buffer for tool failure, setup delays, and external processing.

7. Review Their Workload & Machine Capacity

A supplier making your part on a machine that’s overbooked = late deliveries.

Ask:

How many machines do they have for your part type?

What % of that machine’s time is currently booked?

Do they take urgent orders? How do they prioritize?

You’re not just outsourcing. You’re booking machine time.

8. Evaluate Communication Speed & Technical Clarity

Do they reply within hours? Or days?

Can they:

Suggest alternate tolerances to save cost?

Spot drawing errors or missing views?

Offer packaging/dispatch suggestions?

🧠 A good CNC supplier is not a passive vendor. They’re a smart extension of your engineering team.

9. Visit Their Factory (or Do a Virtual Audit)

The best decision you’ll ever make is to step into their shop.

Look for:

Clean layout & visual SOPs

Part traceability

Worker safety

Raw material segregation

Tool crib & coolant management

If you can’t go in person, ask for a live video walkthrough — genuine shops never say no.

10. Think Long-Term: Ask About Scaling

You may need 20 parts today, but what about 2000 next year?

Ask:

Can they scale with you?

Do they have tier-2 partners for overflow?

How do they manage multiple POs and revisions?

The best CNC partner is not just a one-time order taker.

They grow with you — from prototype to mass production.

Conclusion: Choose a Partner, Not a Vendor

The best CNC machining service isn’t always the cheapest.

It’s the one that saves you time, stress, and rework over the long run.

At TheSupplier.in, we’ve already vetted and ranked 20,000+ Indian suppliers for quality, delivery, and price.

When you upload your drawing, our technical team evaluates your part and handpicks the best-fit supplier — so you don’t have to search, negotiate, or follow up.

Ready to Choose Right?

Upload your drawing at www.thesupplier.in

Let’s help you build better, faster, and smarter.