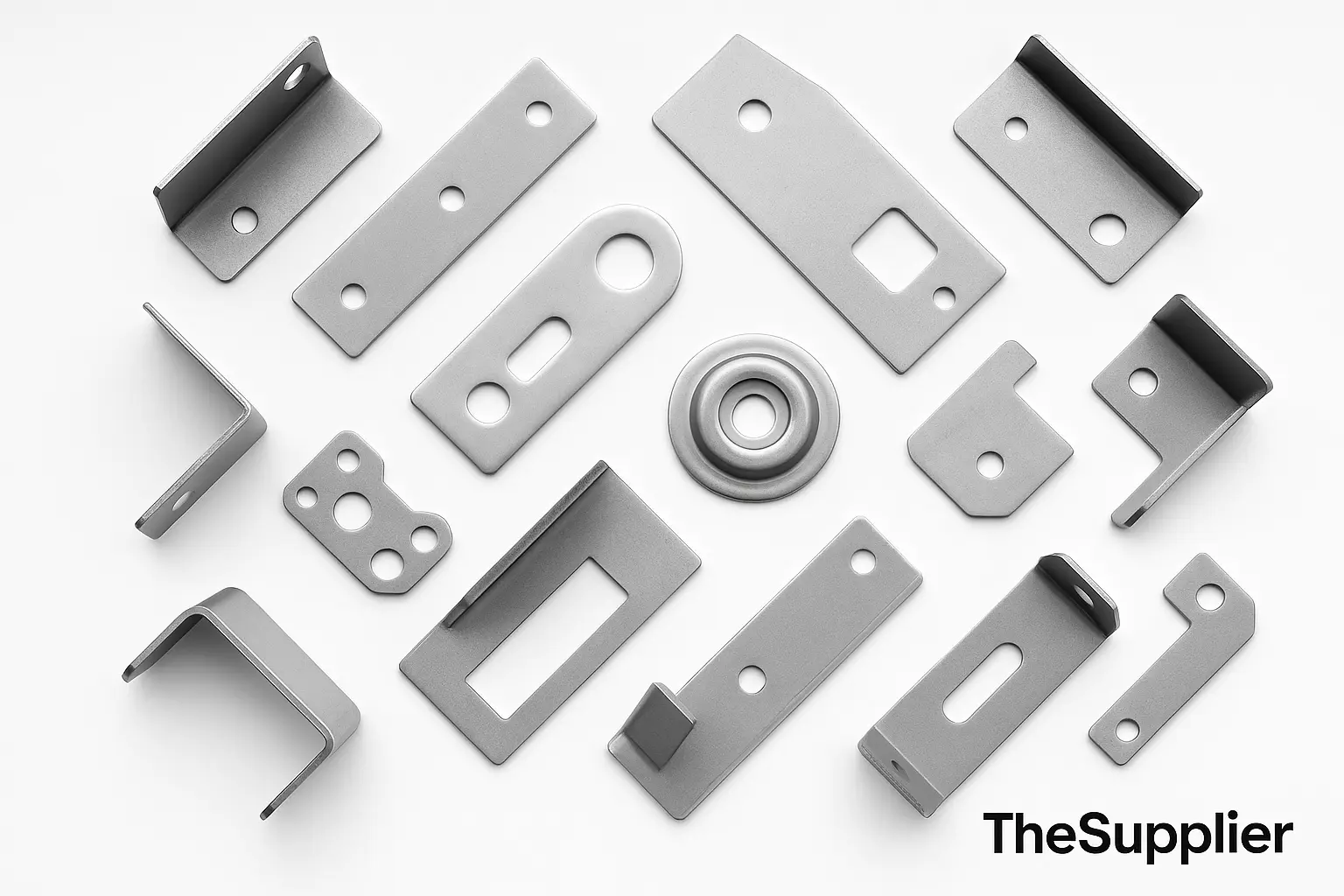

Sheet Metal Fabrication — Stamping & Laser Cutting

We’re not a welding shop. TheSupplier® delivers die-based stamping and laser cutting with managed QC & global delivery.

Why Buyers Choose TheSupplier

We specialize in sheet metal stamping (die-based, high-volume) and laser cutting (fast, flexible) — with DFM support, tight tolerances, and export-grade QC.

Stamping for Scale

Progressive/compound dies for repeatability and low cost per part after tooling.

- Tool design + DFM

- Medium → Mass production

- ISO 2768 guidance

Laser Cutting for Flexibility

No tooling cost, quick changeovers — perfect for prototypes and small batches.

- Clean edges, deburr available

- Nesting optimization

- Fast lead times

Quality & Inspection

In-process & final inspections with documented reports; we own the outcome.

- FAI / PPAP support

- Traceable instruments

- Lot-wise packing & labels

Tooling & DFM

Early DFM reduces cost. Clear tooling ownership, maintenance & amortization plans.

- Design review

- Trial runs

- Maintenance plan

Materials & Finishes

CRCA, SS304/316, Al 5052/6061, GI, copper, brass with certified finishes.

- Zinc plating, powder coat

- Anodizing (Al), passivation (SS)

- Certificates on request

Delivery & Logistics

One accountable partner from supplier selection to export documentation.

- Export packing standards

- On-time dispatch

- Global shipping support

Capabilities Overview — Stamping & Laser Cutting

TheSupplier® matches the right process to your part: die-based stamping for scale and laser cutting for flexibility. Share drawings for exact DFM & quote.

Laser Cutting (Flat Sheet)

⚡ Final specs depend on geometry, thickness, batch size & finish. We’ll recommend stamping vs laser based on total cost & quality.

Stamping vs Laser Cutting vs Fabrication

Choosing the right process saves cost and lead time. Here’s how stamping, laser cutting, and general fabrication compare:

| Criteria | Sheet Metal Stamping | Laser Cutting | General Fabrication |

|---|---|---|---|

| Process | Die & press based (progressive/compound) | High-power laser cuts flat sheet | Cutting, bending, welding, assembly |

| Best for | Medium → Mass production, repeatable parts | Prototypes, small-to-mid batches, complex shapes | Fabricated frames, welded structures |

| Tooling | Requires dies & tooling (one-time cost) | No tooling cost; fully digital | Jigs/fixtures, minimal hard tooling |

| Unit cost | Lowest at volume (tooling amortized) | Higher per part, but no tooling investment | Varies; labor-intensive |

| Tolerances | Tight, repeatable; ISO 2768 guidance | Clean edges; deburr if needed | Depends on welder/fabricator skill |

| Lead time | Tool design + trials → then very fast | Fastest (direct from CAD) | Moderate; multiple manual steps |

| Industries | Automotive, appliances, electronics | Aerospace, prototyping, consumer products | Construction, heavy equipment, custom jobs |

⚡ We recommend stamping when volumes justify tooling, and laser cutting when speed & flexibility matter. Fabrication is best when welded assemblies are required.

Sheet Metal Cost Drivers

What actually drives your part cost? Here are the key factors for stamping and laser cutting at a glance.

Tooling Investment

Progressive or compound die — upfront cost, but lowest unit price at scale.

Amortization

Tooling cost spread across volume — higher volume = lower per-piece cost.

Cycle Time

High-speed presses produce thousands/hour, reducing cost per part.

Material Utilization

Blanking layout & scrap rate affect raw material cost share.

Laser Machine Time

Cut length, complexity & piercing time directly impact cost.

Thickness

Thicker sheets = slower cutting speed = higher per-piece time.

Batch Size

Bigger runs = better rates; laser is ideal for prototypes & low runs.

Nesting Efficiency

Optimized layouts minimize scrap, lowering material usage.

⚡ Rule of thumb: Laser for prototypes or small runs. Stamping for higher volumes where tooling pays back fast.

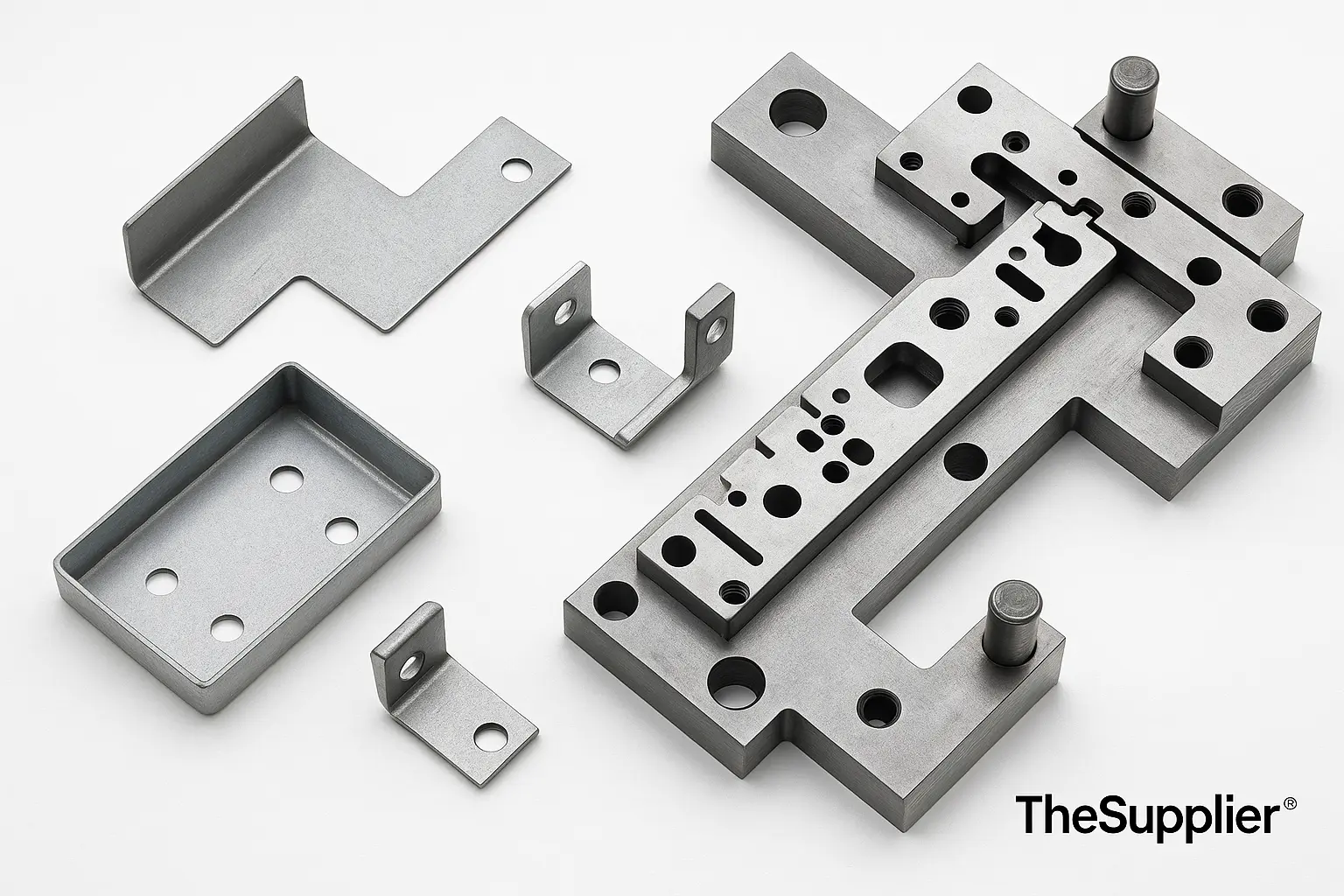

Tooling & Die Development

TheSupplier® manages the complete tooling lifecycle — from design review to ownership models. Here’s how we deliver reliable dies for high-volume stamping.

DFM Review

Optimize design

Die Types

Prog. / Comp.

Trials

FAI / PPAP

Maintenance

Sharpen / Regrind

Ownership

Buyer / Amort.

Quality & Inspection

Every shipment from TheSupplier® is backed by 3-stage QC — incoming, in-process, and final inspection — with documented reports and traceability.

Inspection Coverage

- Material test certificates (MTCs) verified

- Dimensional checks against CAD/drawing

- Surface finish & burr-free confirmation

- Lot-wise packing & traceability

- Final visual + export packing audit

Materials & Finishes

Certified CRCA, Stainless, Aluminum, GI, Copper & Brass with export-grade finishes. Pick the tab to see specs.

Common Grades (Sheet)

We’ll confirm achievable thickness, bend radii, and tolerances per drawing and lot availability.

| Material | Typical Thickness | Notes |

|---|---|---|

| CRCA | 0.6–6.0 mm | Good for stamped brackets; economical. |

| Stainless 304/316 | 0.5–4.0 mm | Corrosion-resistant; finishing options incl. passivation. |

| Aluminum 5052/6061 | 0.8–6.0 mm | Lightweight; anodizing available. |

| GI | 0.6–3.0 mm | Zinc-coated steel; good for enclosures. |

| Copper / Brass | 0.4–3.0 mm | Electrical parts, busbars, terminals. |

Tolerances & Bending

Exact values per drawing; if unspecified, we reference general ISO 2768 guidelines.

- Flat parts: Laser-cut edges deburred on request.

- Formed parts: Minimum bend radius depends on grade & thickness.

- Stamping: Tight repeatability when die is optimized; FAI/PPAP on request.

Surface Finishes

| Finish | Suitable Materials | Typical Use |

|---|---|---|

| Zinc Plating | CRCA, GI | Corrosion protection for brackets/fasteners. |

| Powder Coating | CRCA, SS, Al | Durable color finish for panels & enclosures. |

| Anodizing | Aluminum | Wear resistance & cosmetic finish; clear/black. |

| Passivation | Stainless | Enhances corrosion resistance after machining. |

Certification & QA

- Material certificates (MTCs) available.

- Coating thickness test (microns) on request.

- Salt spray/adhesion tests as per spec.

Industries We Serve

Our sheet metal stamping & laser cutting solutions power global supply chains across multiple industries.

Automotive

Brackets, panels, clips, and assemblies with tooling longevity.

Industrial Equipment

Precision components for machines, enclosures, and hardware.

Electrical

Stamped busbars, terminals, and laser-cut sheet enclosures.

Consumer Goods

Appliance brackets, frames, and formed housings for durability.

Aerospace

Lightweight, certified sheet metal parts with QC compliance.

Medical Devices

Laser-cut precision components for devices & instruments.

Procurement-Ready RFQ

We work the way buyers work — NDA, cost drivers, compliance, and clear lead times. Upload drawings and get a manufacturing-ready quote.

NDA & Data Security

We’ll sign your NDA. Files are handled with restricted access and audit trail.

DFM + Cost Transparency

We share cost drivers: material, cycle time, nesting/scrap, finishing, packing.

Compliance & Certificates

FAI/PPAP, MTCs, coating thickness, RoHS/REACH on request.

Export Logistics

Door-to-port/door-to-door per Incoterms with export-grade packing.

Sheet Metal FAQ

Quick answers about stamping, laser cutting, tooling, tolerances, lead time, and exports.