Accurate Holes, Every Time

Through-hole & Blind-hole Drilling

Expert CNC drilling for metals and plastics — including deep-hole drilling, countersinking, tapping, and high-speed multi-axis drilling.

What is CNC Drilling?

CNC drilling is a machining process where computer-controlled drills create precise, repeatable holes. It covers everything from through-holes and blind-holes to countersinking, tapping, and deep drilling — ensuring accuracy and consistency across metals and plastics.

Hole Types

Through, blind, counterbore, countersink, and tapped threads.

Consistency

Tight positional accuracy and burr-controlled finishes.

Range

Suitable for prototypes, small batches, and large-scale production.

Materials

Aluminum, stainless, mild steel, brass, copper, Delrin, nylon, PTFE.

Learn more in our CNC Machining and CNC Milling sections, or see all Capabilities.

Why Choose TheSupplier for CNC Drilling?

Buyers worldwide rely on TheSupplier for precision CNC drilling. Our vetted supplier network, strict QA, and deep capacity ensure on-time delivery and competitive cost for every order — from one-off prototypes to mass production.

High Accuracy

Burr-free drilling with tight positional tolerances.

Fast Turnaround

Rapid lead times powered by 20k+ vetted suppliers.

Multi-Material

Aluminum, stainless, brass, copper, plastics, and more.

Competitive Pricing

Idle capacity & bulk leverage deliver better cost savings.

Global Delivery

Air and sea shipping with full customs documentation.

Quality Assurance

ISO-aligned inspections and CMM reports available.

Ready to experience reliable CNC drilling? Upload your drawings now →

CNC Drilling Capabilities

Our CNC drilling services cover a wide range of hole-making requirements—from standard through-holes to advanced deep drilling and tapping. Every job is executed with precision, consistency, and speed.

Through Holes

Accurate drilled holes with clean entry and exit, suitable for fastening and assemblies.

Blind Holes

Controlled depth drilling with flat or chamfered bottoms, ideal for tapped features.

Deep-Hole Drilling

Up to 25×D depending on material and tool, with coolant-assisted accuracy.

Countersinking

Chamfered openings for flush fasteners or surface finishing requirements.

Tapping

Thread creation (M2–M24 typical) with high repeatability and gauge-checked quality.

Multi-Axis Drilling

5-axis setups for angled holes, compound geometries, and complex parts.

Not sure which option fits your part? Share your drawing →

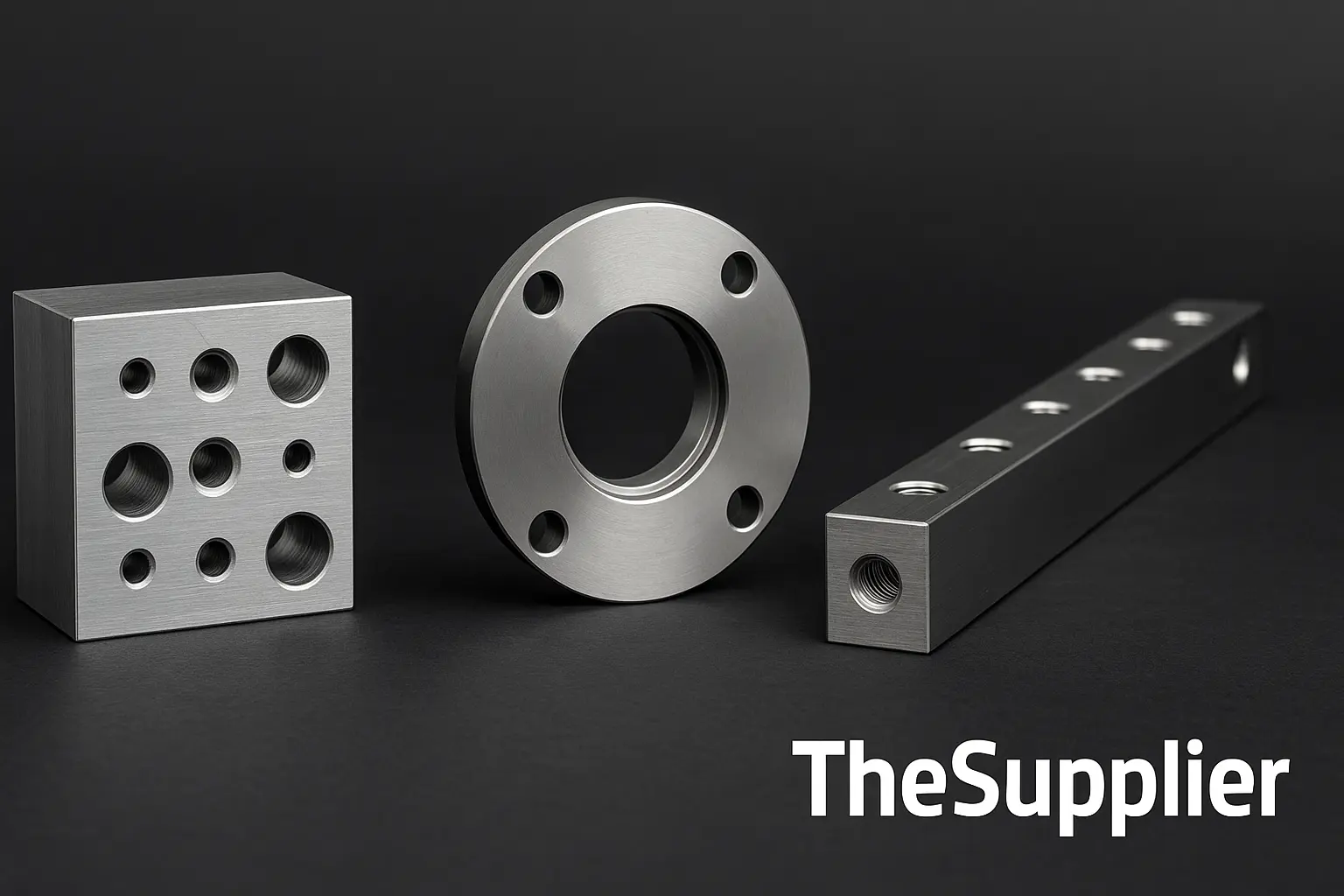

Real CNC Drilling Work — Multiple Components

A single view of multiple CNC drilled parts — showcasing through-holes, blind-holes, countersinking, and tapping delivered by TheSupplier. One collage proves the depth of our capability.

Want your project featured here? Upload your drawing →

Supported Materials for CNC Drilling

We drill across a wide range of metals and engineering plastics — optimized feeds, speeds, and tooling for every material.

Industries We Serve

From automotive to aerospace, TheSupplier delivers CNC drilling parts across diverse industries — meeting strict standards for quality, cost, and lead time.

Automotive

Engine parts, brackets, housings, chassis drilling.

Aerospace

Lightweight alloys, precision holes for structures & interiors.

Industrial

Machinery bases, jigs, fixtures, heavy equipment drilling.

Oil & Gas

Flanges, valves, and high-pressure drilled components.

Medical

Stainless & titanium drilled parts for medical devices.

Electronics

Precision holes in enclosures, heat sinks, and connectors.

Processes We Offer

Beyond CNC drilling, TheSupplier provides a complete suite of machining and fabrication services — enabling us to handle prototypes and production across all complexity levels.

Ready to Drill Your Next Part?

Fast quotes, precise hole-making, and reliable delivery from prototype to production.

CNC Drilling Guides & Resources

Hole quality, H7 bores, when to ream, and buying tips to avoid tolerance stack-up on assemblies.

CNC Machining Tolerances Explained

What ±0.01 mm really means for hole true position, bores, and fits.

Read guide →How to Choose the Right CNC Machining Service

When drilling + reaming beats boring; supplier signals that protect hole quality.

Read guide →CNC Milling Surface Finish Guide

Finish impacts bore size after anodize/plating—how to plan compensations.

Read guide →CNC Drilling — FAQs

Quick answers to the most common questions buyers ask us.