AI in CNC machining is no longer “future tech.” It’s already changing how parts are programmed, quoted, and delivered. If you still wait days for quotes or fight avoidable delays, this is the moment to reset your sourcing and shop-floor playbook.

Here’s what you’ll discover:

- ⚑ The 7 shifts AI is creating across programming, quoting, and uptime

- ✅ How buyers get faster quotes and tighter lead times

- ❌ Why suppliers without AI will lose repeat RFQs

- ★ Real example: CloudNC’s CAM Assist cutting ~80% programming time

Why AI is rewriting CNC machining

Across modern shops, AI in CNC machining automates toolpaths, estimates cycle time and cost, predicts tool wear, and standardizes quoting. Buyers get quotes in hours (not days). Suppliers process more RFQs without adding headcount. Independent reports and user stories consistently show big gains in programming speed and reliability.

The 7 critical shifts buyers & suppliers must know

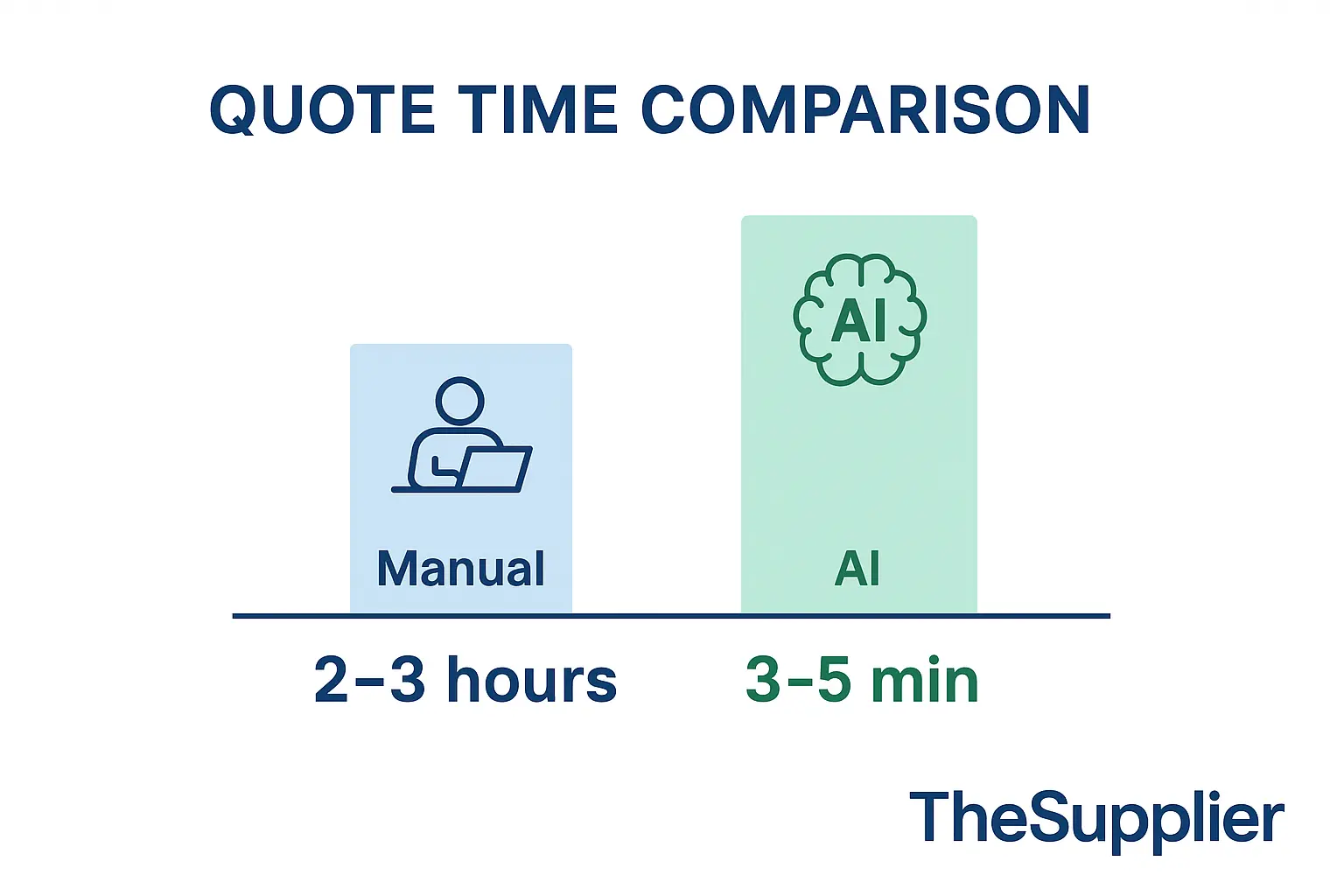

1) ⚑ Faster quoting, shorter sourcing cycles

AI toolpath planning and cost estimation produce credible quotes in minutes. Buyers can compare more suppliers; shops raise response rates and win more work.

2) ✅ ~80% reduction in programming time

AI suggests strategies for feeds, speeds, and approach. Machinists fine-tune instead of coding from scratch. That’s how AI in CNC machining compresses CAM time from hours to minutes.

3) ❌ Lower scrap and defects

Virtual cut simulation flags chatter, collisions, and coolant issues before metal is cut. Buyers see consistency rise; suppliers protect margin by preventing rework.

4) ⏱ Predictive maintenance for uptime

AI monitors spindle load, vibration, and heat to forecast tool or machine failure. Schedules shift from reactive to proactive—delivery dates become believable.

5) ★ Digital-twin integration

CAD → CAM → CNC → QC closes in a data loop. Simulation reduces fixture mistakes and tolerance stacking, a frequent failure on complex geometries.

6) $ True cost visibility

AI decomposes cycle time, tool wear, material removal rate, and setup into precise dollars. Buyers negotiate with facts; suppliers avoid under-quoting.

7) ⚠ Competitive edge (or risk)

Early adopters of AI in CNC machining quote faster, price smarter, and miss fewer deadlines. Late adopters appear slow and costly, and lose repeat RFQs.

Real-world example: AI CAM Assist

Shops adopting AI CAM have reported programming reductions close to 80% and far faster quoting. Read the product overview from CloudNC here: CloudNC CAM Assist (external).

Buyer perspective: how to leverage AI now

- ⫸ Add “AI in CNC machining preferred” to your RFQs.

- ⫸ Request cost breakdowns by cycle time, tool wear, and setup.

- ⫸ Source through partners who prove digital quoting and predictive maintenance.

- ⫸ Explore our Capabilities and submit your drawing via Get a Quote (RFQ) to match with AI-ready shops.

Supplier perspective: how to stay competitive

- ★ Advertise “AI in CNC machining ready” in your profile and proposals.

- ★ Respond same-day using AI quoting; attach cycle-time evidence.

- ★ Train machinists to guide (not replace) AI toolpaths; standardize templates.

- ★ Use predictive maintenance to protect promised delivery dates.

- ★ Refer buyers to our CNC Machining page for capability coverage and tolerances.

Comparison: manual vs AI workflow

| Task | Manual Time | AI Time | Buyer / Supplier Impact |

|---|---|---|---|

| Toolpath programming | 2–3 hours | ~10 minutes | Faster quotes; higher programmer throughput |

| Quoting | 1–2 days | < 1 hour | More bids; better pricing clarity |

| Tool wear prediction | Reactive | Proactive | Less downtime; fewer defects and rework |

2030–2035 outlook

Expect broader automation, richer digital-twin validation, and near-continuous machining. As AI in CNC machining scales, buyers will compare suppliers on digital maturity as much as on price.

Quick action checklist

For Buyers

- ✅ Require AI-enabled quoting and cost breakdowns

- ✅ Compare delivery reliability: AI vs non-AI suppliers

- ✅ Submit drawings via Get a Quote (RFQ) to reach AI-ready partners

For Suppliers

- ☑ Publish AI capability and sample cycle-time evidence

- ☑ Standardize CAM templates and predictive maintenance

- ☑ Aim for same-day RFQ responses

- ☑ Share your scope via CNC Machining & Capabilities

Conclusion: The shops that adopt early will quote faster, cut cheaper, and deliver reliably. The buyers who demand it will unlock real savings. Ready to move? Get a Quote and we’ll match you with AI-ready partners.