CNC turning components power everything from automotive drivetrains to aerospace landing gear and critical oil-&-gas connections. This guide explains the parts, applications, tolerances, finishes, materials, cost drivers—and how TheSupplier turns your drawings into reliable production at global scale.

What you’ll learn

- Which CNC turning components (shafts, bushings, flanges) dominate demand—and why.

- Best materials, achievable tolerances, and surface finishes for production.

- How to cut cost per piece without risking quality or delivery.

- Real RFQ → PO → Turning → QC → Dispatch timeline from our 20k+ supplier network.

- FAQ answers on threads, lead times, ISO docs, inspection reports, and more.

What is CNC Turning?

CNC turning is a subtractive machining process where a bar or forging rotates in a chuck while a computer-controlled tool removes material to create precise cylindrical forms. Common CNC turning components include shafts, bushings, flanges, pins, rollers, and couplings. It excels at concentricity, roundness, and repeatability across small to very large volumes.

Compare to milling (which removes material with a rotating cutter on stationary workpieces), turning is faster and more economical for rotational parts. Complex features—threads, undercuts, knurls—are easily integrated in a single setup.

See our full capability overview: TheSupplier Capabilities.

Turning vs Milling (Quick Compare)

| Aspect | CNC Turning | CNC Milling |

|---|---|---|

| Best for | Rotational parts (shafts, bushings, flanges) | Prismatic/3D geometries |

| Accuracy | ±0.01–0.05 mm typical | ±0.02–0.10 mm typical |

| Cycle time | Very fast for long runs | Varies by complexity |

| Cost per piece | Lower for cylindrical parts | Lower for non-rotational parts |

Core CNC Turning Components (High-Volume)

Shafts

- Drive, motor, pump, gearbox shafts with tight runout & concentricity.

- Finishes from turned (Ra 3.2–1.6 μm) to ground (Ra ≤0.8 μm).

- Common: 4140/4340 steel, SS 304/316, 7075-T6 aluminum.

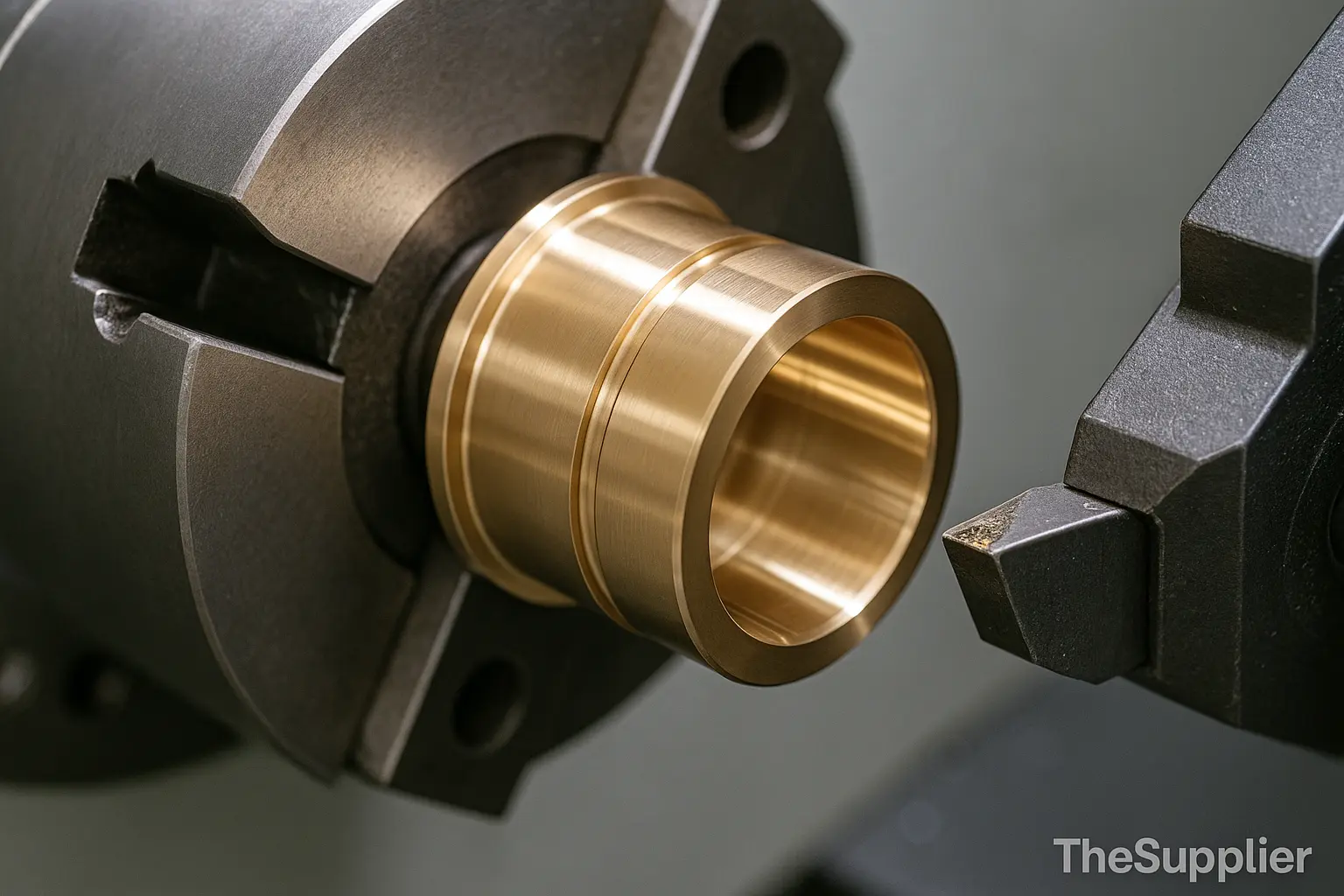

Bushings

- Slip-fit/H7 bores, grooves for lubrication, chamfers & lead-ins.

- Materials: Brass, Bronze, Delrin (POM), PTFE, SS 303/316.

- Plating/anodize options for wear & corrosion resistance.

Flanges

- Pipe, blind, slip-on, threaded flanges for oil & gas/chemical.

- Faces: raised, RTJ; threads per ASME/ISO; concentricity critical.

- See: Stainless Steel Flange • USA

Pins & Couplings

- Dowel, taper, clevis pins; jaw/beam couplings; custom adapters.

- Threads: UNC/UNF/Metric; keyways & cross-holes (live tool).

Rollers

- Conveyor/textile/paper rollers; hardening + precision grinding.

- Balancing & coating options (chrome, nitriding, polymer).

Fittings & Adaptors

- Hydraulic/pneumatic connectors, ferrules, compression nuts.

- Leak-critical specs with thread gauges & pressure tests.

Where CNC Turning Components Are Used (By Industry)

- Drive/pinion shafts, bushings, hubs

- ABS & powertrain fittings

- Guide bushings, actuators, coupling parts

- High-strength 17-4, Ti-6Al-4V

- Flanges, threaded adaptors, RTJ rings

- NACE materials, pressure tested

- Surgical tool bushings, connectors

- SS 316L, PEEK, tight finish

- Rollers, pins, custom fasteners

- Automation spares at volume

Explore full stack: Capabilities • CNC Machining Services

Best Materials for CNC Turning Components

Choosing the right material balances strength, machinability, corrosion resistance, weight, and cost. Here’s a buyer-friendly view:

| Material | Why Choose It | Typical Turned Parts | Machinability |

|---|---|---|---|

| Carbon Steel (4140/4340) | High strength & toughness | Shafts, couplings, pins | Medium |

| Stainless Steel (304/316/316L) | Corrosion resistance, sanitary | Flanges, bushings, fittings | Medium-Low |

| Aluminum (6061, 7075-T6) | Lightweight, fast to machine | Aerospace shafts, adaptors | Very High |

| Brass/Bronze | Excellent machinability & sealing | Bushings, ferrules, valves | Very High |

| Titanium (Ti-6Al-4V) | High strength-to-weight | Aerospace bushings/shafts | Low |

| Engineering Plastics (Delrin, PTFE, PEEK) | Low friction, chemical resistance | Precision sleeves/bushings | High |

Tip: For weight-critical projects, estimate quickly with our Metal Weight Calculator.

Tolerances You Can Expect

- Shafts: Ø tolerances ±0.01–0.03 mm; runout ≤0.02–0.05 mm (spec-dependent).

- Bushings: Bore H7 (e.g., Ø20 H7 = +0/+0.021 mm); roundness ≤0.01–0.02 mm.

- Flanges: Bolt circle true position per GD&T; face flatness within 0.05–0.10 mm.

- Threads: Metric/UNC/UNF verified with GO/NO-GO gauges; sealing per spec.

Deep dive on limits & fits: CNC Machining Tolerances Explained.

Surface Finishes

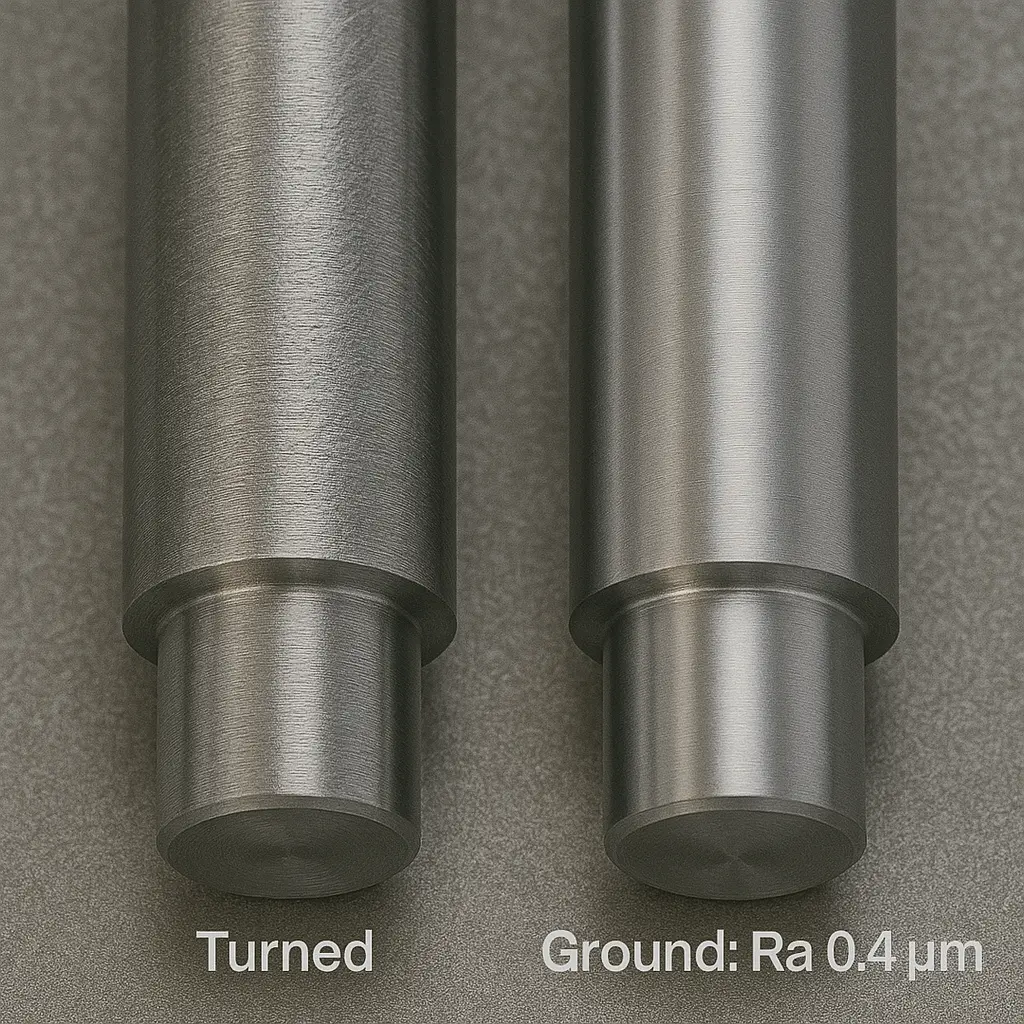

| Finish | Typical Ra | Where Used |

|---|---|---|

| Turned | Ra 3.2–1.6 μm | General shafts, flanges |

| Ground | Ra ≤0.8 μm | Wear surfaces, seals, bearings |

| Honed/Polished | Ra ≤0.4 μm | Hydraulic fits, medical |

| Anodize/Plating | As-processed | Corrosion/wear aesthetics |

Cost Drivers for CNC Turning Components (and How to Reduce Them)

1) Material & Bar Yield

Cost scales with alloy price and how efficiently your geometry nests within standard bar sizes. Long parts with large OD-to-ID waste push cost up.

- Optimize OD/ID to common bars.

- Consider near-net forgings for large flanges.

2) Cycle Time

Roughing depth of cut, number of passes, live-tool ops, and deburring add seconds that compound across 1000+ pcs.

- Combine ops where possible; avoid unnecessary undercuts.

- Standardize radii/chamfers.

3) Tolerances & Inspection

Tight fits (H7/g6), low runout, and CMM sampling levels affect cost.

- Specify only critical callouts in GD&T.

- Agree sampling (AQL) upfront.

4) Secondary Finishing

Grinding, plating, anodizing, passivation add time and logistics.

- Batch finishes by color/spec.

- Use protective masking to reduce rework.

5) Order Quantity & Setup

Larger batches amortize setup/tooling. For recurring demand, blanket POs lower unit cost and secure machine time.

- Plan releases (e.g., 3× monthly) to stabilize pricing.

6) Packaging & Logistics

Rust prevention, custom trays, and export documentation add cost but reduce damage and returns.

- Right-size protective packaging for shafts & flanges.

Ready to optimize? Share your drawing and we’ll propose a cost-down plan without compromising quality.

CNC Turning vs Manual Lathe

| Feature | CNC Turning | Manual Lathe |

|---|---|---|

| Accuracy | ±0.01–0.05 mm | ±0.1 mm |

| Complex Features | Threads, grooves, tapers, live-tool ops | Limited |

| Repeatability | Excellent across 1000+ pcs | Operator dependent |

| Cost per piece | Lower for rotational parts | Higher for volume |

| Lights-out | Yes (automation) | No |

Real-World Case: Turned Flanges for Gulf Customer

Objective: 500 pcs stainless steel flanges with RTJ face, certified for export. We leveraged our 20,000+ vetted suppliers to lock pricing, capacity, and QC in one managed workflow.

Drawing + specs received, target price shared.

Runout & face flatness risks addressed; gauge plan set.

Blanket order with two releases to secure machine time.

Threads & grooves cut; faces prepared for RTJ.

CMM + thread gauges; finish verified; passivation.

Rust-proof packaging; export docs; on-time shipment.

Quality & Inspection

- CMM/height gauge reports with ballooned drawings (on request).

- Thread gauges (GO/NO-GO), surface roughness checks, runout logs.

- Material test certificates (MTC), passivation/anodize certs.

- Sampling plans aligned with AQL per order criticality.

Ask for sample PPAP/ISIR if your project requires automotive-grade documentation.

FAQs on CNC Turning Components

What tolerance can I expect for CNC turned shafts?

Typical diameter tolerances are ±0.01–0.03 mm with runout ≤0.02–0.05 mm depending on length, setup, and fixturing. For bearing fits (g6), we align tools, control thermal drift, and verify on CMM.

What surface finish is normal for bushings?

Turned finish of Ra 1.6–3.2 μm is common; for sliding fits we recommend grinding/honing to Ra ≤0.8–0.4 μm. Add lubrication grooves and edge breaks for assembly friendliness.

Which materials are most cost-efficient?

Aluminum 6061/7075 and brass offer excellent machinability. For corrosion resistance choose SS 304/316. For high-strength shafts, 4140/4340 is a good balance of cost and performance.

Can turned flanges be anodized or plated?

Yes. Aluminum flanges can be clear/hard anodized; steel parts can be zinc-nickel or phosphate coated; stainless can be passivated. We mask sealing faces as required.

What order quantities suit CNC turning best?

From prototypes to 10k+ pcs. Economies of scale appear quickly after 100–200 pcs when cycle time and setup are optimized.

How can I reduce cost per piece?

Match features to standard tools, avoid ultra-tight non-critical tolerances, batch finishes, and consider blanket POs to lock machine time and pricing.

When should I choose milling instead?

For prismatic parts with pockets, slots, and complex 3D surfaces, milling is preferred. For rotational parts with threads/grooves/tapers, turning wins on speed and cost.

What QC documents will I receive?

Standard dimensional reports, thread gauge results, and finish checks. On request: CMM reports with ballooned drawings, MTC, PPAP/ISIR, and plating/anodize certificates.

Do you handle both prototypes and mass production?

Yes. We rapidly prototype to validate design and then scale to volume using our 20k+ suppliers with consistent tooling and process controls.

What lead time should I plan for?

Prototypes: 5–10 working days depending on finish. Production lots: 2–6 weeks based on material availability, finishing, and logistics windows.

Can you produce custom threads and tapers?

Absolutely. Metric/UNC/UNF/BSW, NPT/BSPT, left-hand threads, and custom tapers are routine with GO/NO-GO gauging.

Do you export to the USA/Europe/Gulf?

Yes. We manage documents, packing, and labeling. Explore: USA flange page and related country pages as we expand.

Ready to Source CNC Turning Components?

Send your drawing for shafts, bushings, flanges, pins, rollers, or couplings. We’ll quote fast, manage quality, and deliver globally.