What EU engineers check first: PN ratings, materials, certificates, and delivery to your plant.

- How an EN 1092-1 flange differs from other standards

- Which PN ratings fit common EU applications

- What EN 10204 3.1 / 3.2 really means for compliance

- Fastest way to get a DDP Europe quote

If you buy flanges in Europe, you already speak the language of the EN 1092-1 flange: metric dimensions, PN ratings, and mill certificates that stand up to audits. This quick guide compresses what plant engineers actually check—so your next order is compliant, on time, and cost-correct.

What is an EN 1092-1 flange?

An EN 1092-1 flange is the European standard flange used across chemical, pharma, food, power, and general industry. Dimensions are metric and pressure is expressed as PN (Pressure Nominal). Common types include slip-on, blind, weld neck, threaded, socket-weld, lap joint, and RTJ.

PN ratings (PN10–PN100): what should you choose?

The PN class on an EN 1092-1 flange indicates allowable pressure at a reference temperature. In practice:

- PN10 / PN16 — utilities, water lines, low-pressure processing

- PN25 / PN40 — most industrial services with safety margin

- PN63 / PN100 — high-pressure or critical duty, often with weld neck/RTJ

Share operating pressure/temperature with your supplier—choosing PN conservatively on an EN 1092-1 flange reduces maintenance risk.

Materials: stainless, duplex, carbon, alloy

Material selection drives lifespan and total cost. For a typical EN 1092-1 flange:

- 316/316L — pharma and food; strong corrosion resistance

- Duplex 2205 / Super Duplex 2507 — offshore, chlorides, higher strength

- Carbon steel (P245GH, C22.8) — non-corrosive services, economical

- Alloy (A182 F11/F22/F91) — high-temperature lines in power/refining

If in doubt, request a quick material recommendation against your medium and temperature. It’s the fastest way to spec the right EN 1092-1 flange.

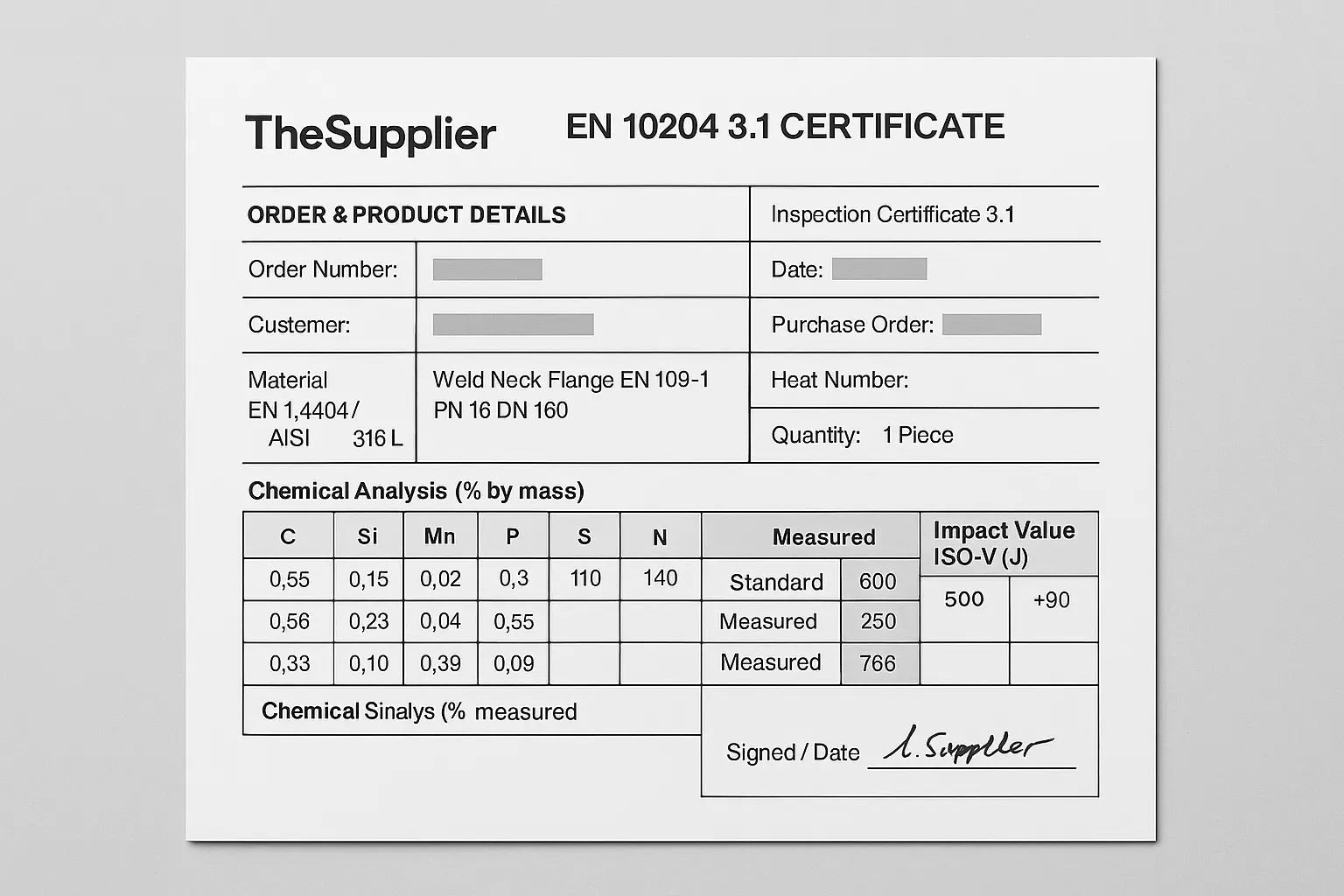

Certificates that matter in Europe: EN 10204 3.1 vs 3.2

EU auditors expect traceability. A 3.1 certificate confirms test results from the manufacturer’s QA department. A 3.2 adds a third-party witness (e.g., TÜV, Lloyd’s). For critical projects, order your EN 1092-1 flange with 3.2 and align inspection scope (PMI, Hydro, UT/RT) in the PO.

Sealing faces and QA checks you should insist on

- Sealing face: verify roughness and finish to protect gaskets

- PMI: confirms grade and chemistry before dispatch

- Hydro: pressure integrity for representative samples or 100% by agreement

- UT/RT: for forged blanks and weld necks where integrity is mission-critical

These checks, attached to your EN 1092-1 flange MTC, reduce line-start delays after delivery.

Need a fast, compliant supply? We manufacture and ship EN 1092-1 flanges with EN 10204 certificates and handle DDP Europe delivery. Get a 24-hour quote →

DDP Europe: realistic timelines & paperwork

Two practical paths: express dispatch for urgent lots (samples, short runs) or standard production with sea freight. Include HS codes and certificate requirements in the RFQ so your EN 1092-1 flange clears EU customs without rework. For plants in Germany, France, Italy, Netherlands, and Spain, DDP saves you coordination time.

How to speed up your quote (and lower price)

- Attach STEP/DWG/PDF or specify size, PN, type, and material

- Share a target price to optimize sourcing quickly

- Provide annual or monthly volume for better cost tiers

Clear inputs let us prioritize machining and forging routes for your EN 1092-1 flange and hold better delivery dates.

Key takeaways

- An EN 1092-1 flange with the right PN and material saves downtime

- Ask for EN 10204 3.1/3.2 and define QA scope in PO

- Use DDP for predictable delivery and fewer handoffs

Ready to source? See our Europe flange page or request a DDP quote now.