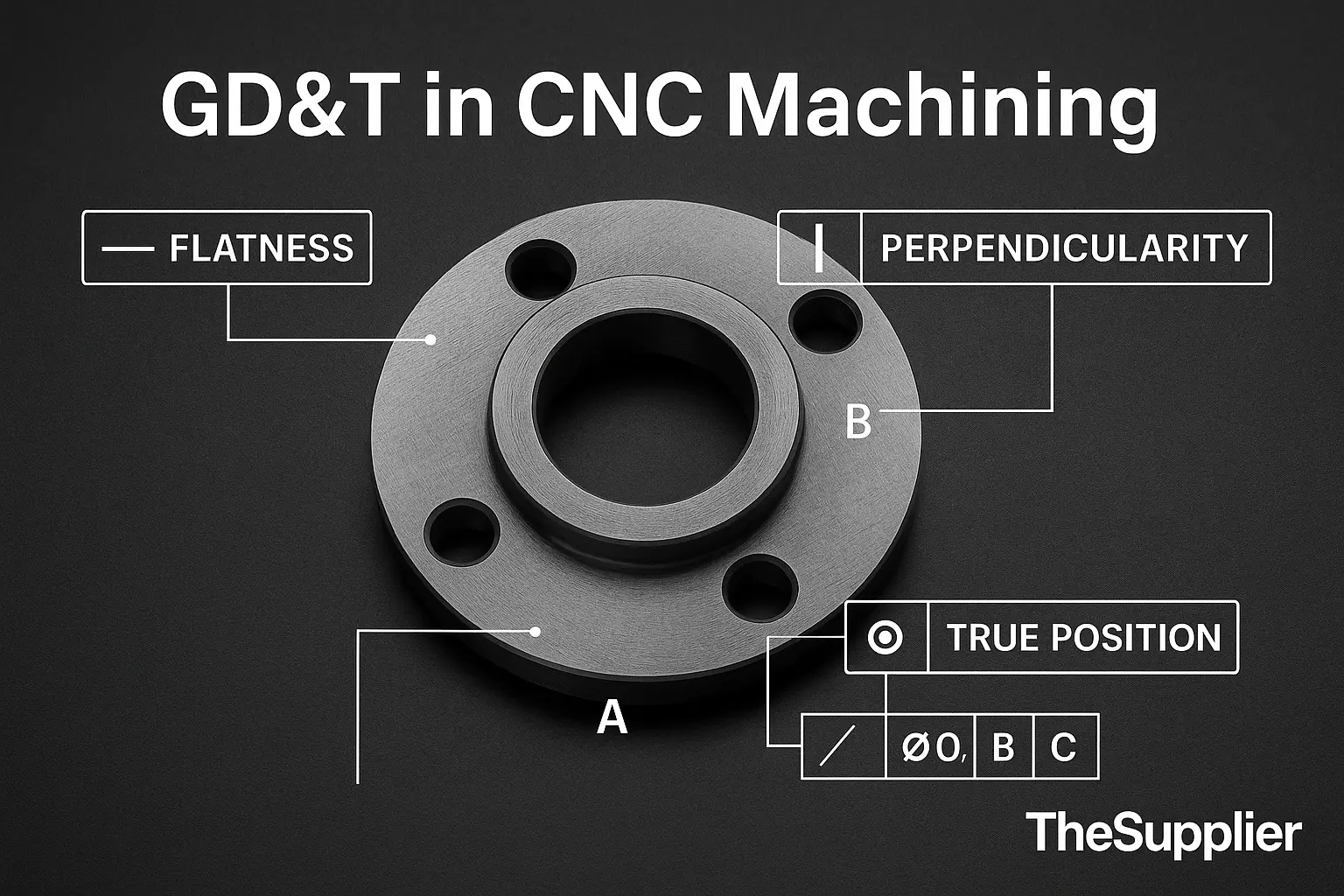

GD&T in CNC Machining: Flatness, Perpendicularity & True Position (Buyer’s Guide)

The only three GD&T callouts buyers really need for CNC parts — explained in plain English, with examples, cost impact, and inspection tips.

Why GD&T matters for buyers

The fastest way to control fit and function—without overpaying—is to specify the right GD&T controls only where they matter. In this guide we focus on three: flatness (surfaces seal properly), perpendicularity (features assemble square), and true position (holes/bores locate correctly).

Cost

Tighter callouts raise cycle time, fixturing, tool wear, and inspection cost. Use the minimum that guarantees function.

Lead Time

Challenging tolerances push parts to slower machines and CMM queues. Good specs keep you in faster lanes.

Quality

Clear GD&T + consistent datums = fewer disputes, smoother approvals, and predictable assemblies.

Explore related services: CNC Machining · CNC Turning · CNC Milling · Metal Weight Calculator

Flatness — controlling a single surface

Flatness is the simplest GD&T form control: it ensures a surface does not deviate beyond a specified zone of two parallel planes. It’s independent of datums and applied directly to one face.

- Best for sealing faces, gasket surfaces, and precision mounting planes

- Prevents wobble or rocking during assembly

- Measured with granite + feeler gauges, or CMM for detailed mapping

Buyer tip: Avoid “super-flat” calls unless functionally needed — tighter than 0.05 mm often adds lapping/grinding cost.

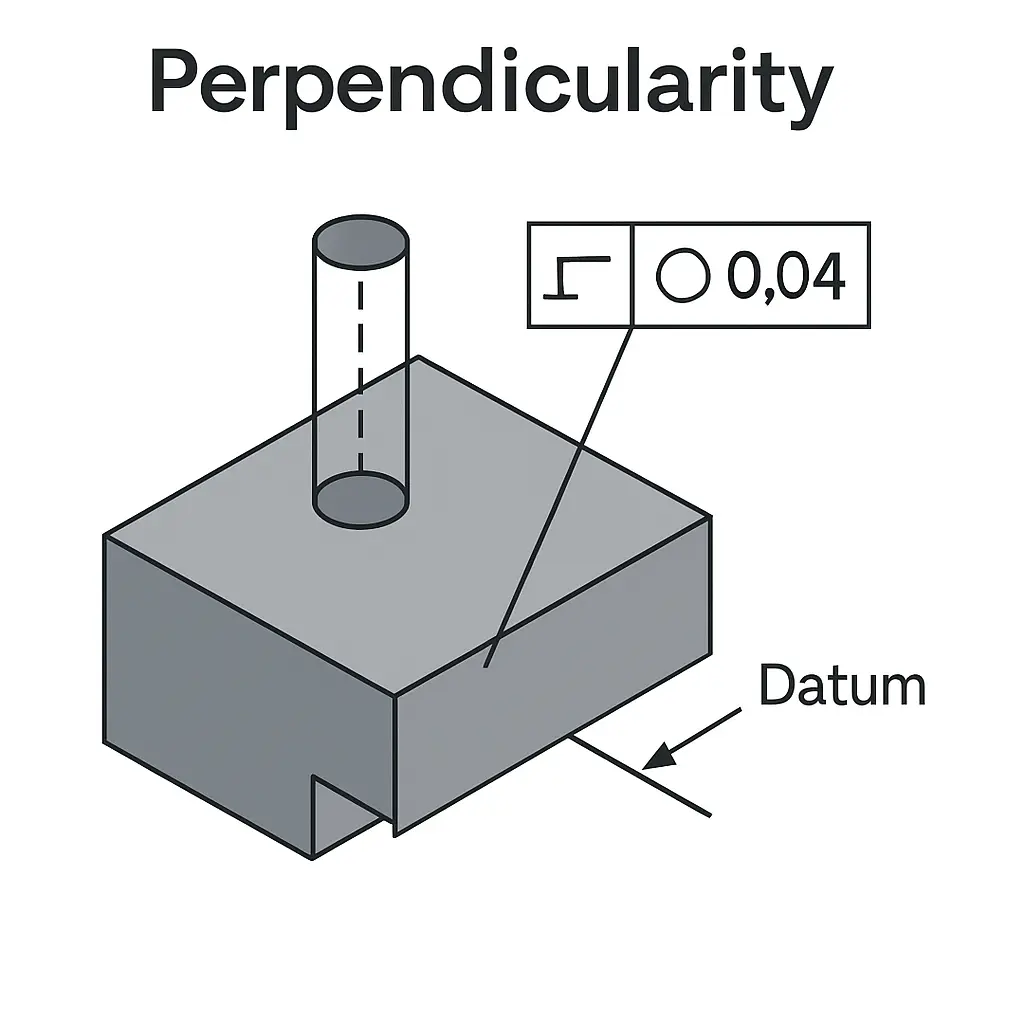

Perpendicularity — keeping features square

Perpendicularity is a location control that ensures one feature (like a bore axis) is square to a datum plane or axis. It’s essential when parts must assemble without misalignment or angular error.

- Controls angularity between a bore and its mounting face

- Common for shafts, bushings, housings where squareness is critical

- Measured with dial indicators, CMM, or specialized fixturing

Buyer tip: Keep perpendicularity at ±0.1 mm per 100 mm length unless functionally tighter — over-specifying drives cost.

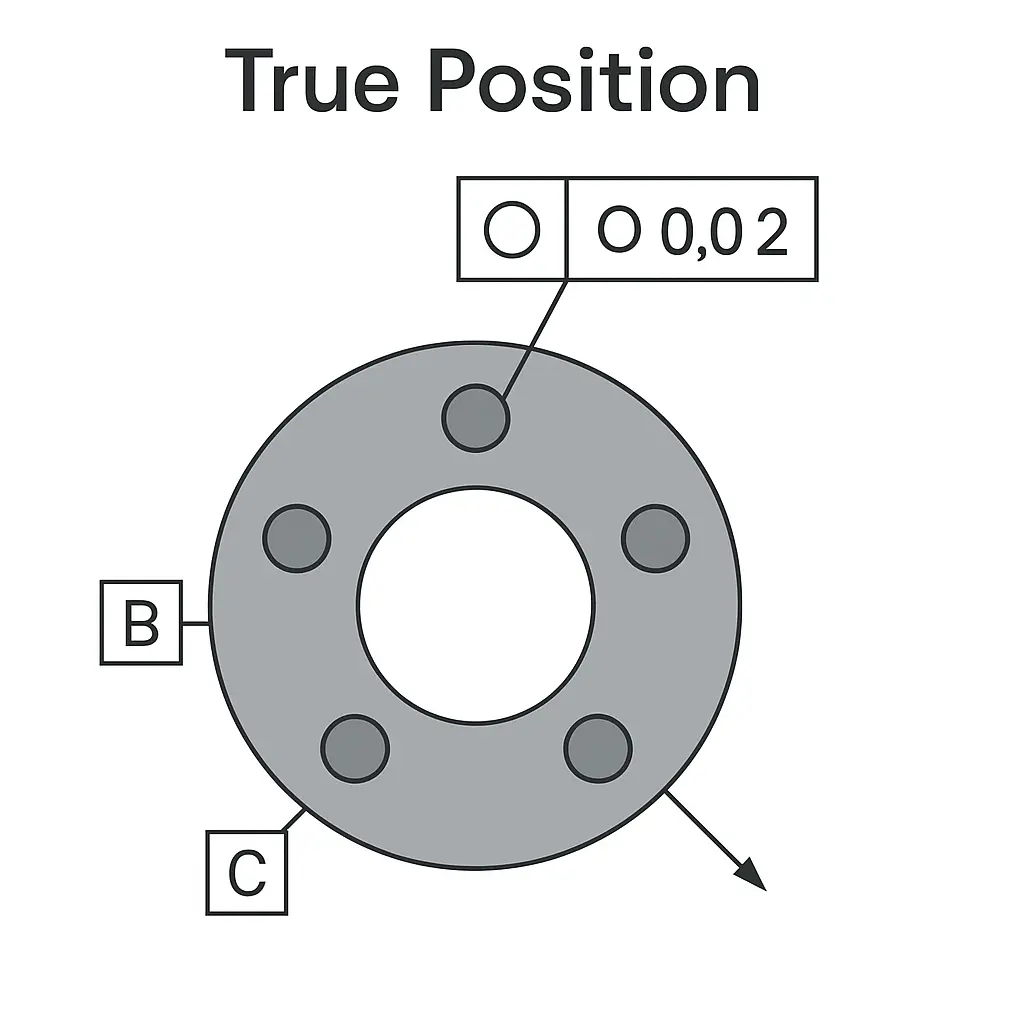

True Position — the all-rounder for holes

True position controls how far the axis or center of a feature can deviate from its exact theoretical location. Instead of box tolerances, it defines a cylindrical zone around the true location.

- Perfect for bolt circles, hole patterns, pins, and slots

- Allows cylindrical tolerance zones — more realistic than ± dimensions

- Inspection is straightforward with CMM or gauge fixtures

Buyer tip: Start with Ø0.20–0.25 mm @ MMC for bolt circles — going tighter quickly raises cost.

CMM & Inspection — choose the right method for each callout

Match the inspection method to your flatness, perpendicularity, and true position. Use lightweight checks for prototypes, scale to CMM for production/PPAP.

Granite + Feeler Gauges (Flatness quick check)

Place the sealing face on granite; sweep feeler gauges to confirm the flatness window. Great as a go/no-go before CMM.

Dial on Square Block (Perpendicularity quick)

Reference the datum face, sweep the bore/slot to see deviation from 90°. Useful to adjust before finish ream/bore.

CMM Pattern Evaluation (True Position)

Establish A (plane), align B (bore axis), clock with C (side flat). Probe pattern to calculate positional error in a cylindrical zone.

Bore/Plug Gauges (Size before position)

Verify feature SIZE first (especially if using MMC). Then evaluate perpendicularity/position—size affects bonus tolerance.

Go/No-Go Fixture (High throughput)

Dedicated positional gauge for fast screening of bolt-circle holes. Use for repeat parts once the design is frozen.

Surface Maps & Reports (PPAP evidence)

Color maps and tabular outputs for flatness/perpendicularity provide clear visuals for buyer sign-off and audits.

Deep dive: CMM & Inspection Reports for CNC Parts · Services: CNC Machining · Standard: ISO 1101 overview

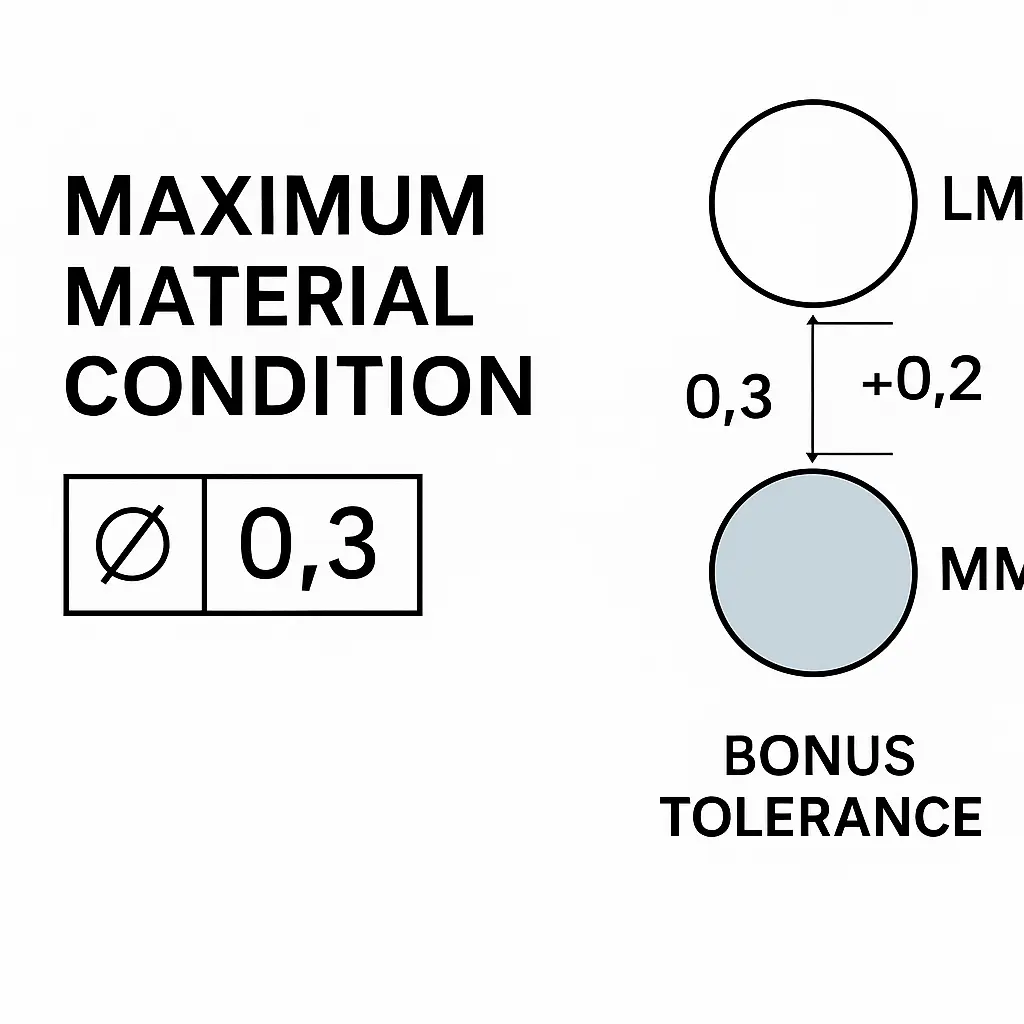

MMC & Bonus Tolerance — faster approvals, fewer rejects

How it works (plain English)

MMC = “maximum material.” For holes, it’s the smallest size; for pins, it’s the largest.

With MMC on true position, any extra clearance automatically converts into extra positional allowance (“bonus”).

This rescues close-to-the-edge parts that still assemble perfectly—reducing scrap without hurting function.

Spec template (copy & tune)

Datums: A = base face, B = pilot bore Ø30, C = side flat

GD&T: ⓣ TRUE POSITION Ø0.20 mm @ MMC to A|B|C (applies to hole axes)

Note: Verify SIZE first (go/no-go); then evaluate position

Related: CNC Drilling & Hole Tolerances · Service: CNC Machining

GD&T FAQs for Buyers

Answers to the most common questions we see on drawings. Keep only one FAQ schema on this page to avoid duplication errors.

Use true position for holes, pins, and bolt patterns—its cylindrical tolerance zone matches round features and simplifies CMM checks. ± boxes often over-reject good parts. See examples above or review our CNC Drilling & Hole Tolerances.

No. Flatness is a form control applied to a single surface and is independent of datums. If you need the surface controlled relative to another surface, consider parallelism instead.

Choose datums that reflect assembly reality. Typical picks: Datum A = sealing/base face, Datum B = primary bore/shaft axis, Datum C = side flat/slot for clocking. Then apply perpendicularity to keep the controlled feature square to A (and aligned via B/C). Need help? See our CNC Machining page.

MMC (Maximum Material Condition) adds bonus tolerance to position when the feature size drifts toward more clearance. It recognizes parts that still assemble perfectly and prevents unnecessary rejection—see the MMC section above.

Not always. Prototype/low-risk parts can use granite, indicators, and gauges. Reserve CMM for critical GD&T features, first-article, or PPAP. We often combine a quick screen with periodic CMM to cut lead time.

A sensible starting point is Ø0.20–0.25 mm @ MMC for milled/reamed holes in common aluminum/steel parts. Tighter than Ø0.10 mm increases jig/boring time and CMM load—justify it with assembly needs. Also review Milling Surface Finish Guide for finishing impacts.

Order CNC Parts with the Right GD&T

TheSupplier manages 20k+ vetted suppliers so your flatness, perpendicularity, and true position needs are produced correctly, inspected properly, and shipped on time. Get parts without rework, delays, or disputes.