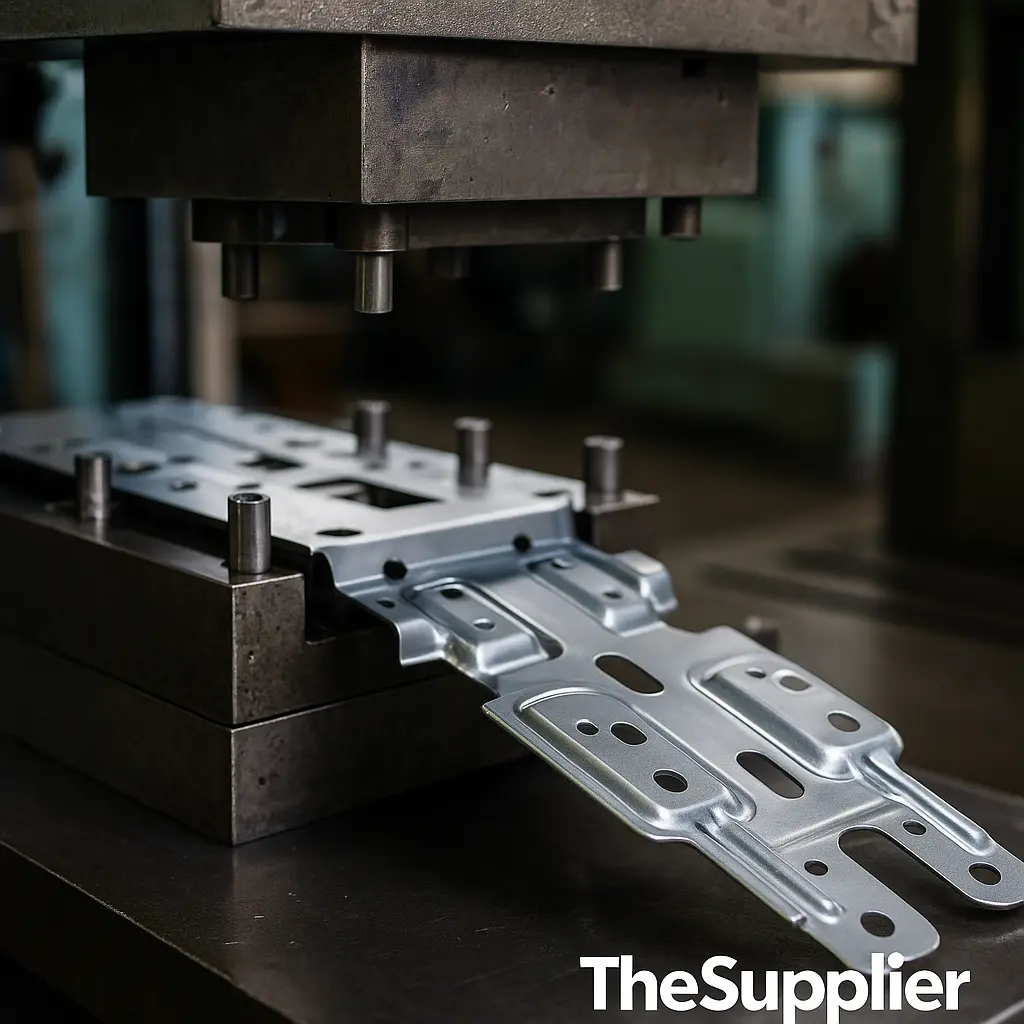

Progressive Die Stamping

Multiple operations in one press stroke—best for high volume, tight repeatability, and lowest cost per part.

Progressive Dies Deep Draw Stamping Transfer Stamping Blanking & Piercing Embossing & Coining

High-volume, repeatable metal stamping for brackets, clips, covers, and complex parts — optimized for mass production with tight tolerances and fast tooling.

Sheet metal stamping is a high-speed manufacturing process that uses precision dies and presses to form flat sheets into complex shapes. It is the most cost-effective solution for mass production of brackets, clips, housings, and structural parts.

Millions of parts at consistent quality and repeatability.

High-volume stamping reduces unit cost compared to machining.

Tight tolerances, complex geometries, and clean finishes.

End-to-end stamping capabilities—from simple blanks to deep draw and progressive dies.

Multiple operations in one press stroke—best for high volume, tight repeatability, and lowest cost per part.

Cylindrical/box shapes with high draw depth—cups, housings, cans.

Part moves station-to-station with fingers—ideal for large or complex forms.

Clean sheared edges and burr control for flat patterns and hole features.

Logos, stiffening ribs, and crisp features with controlled surface finish.

Flanges, hems, beads, offsets—repeatable angles with springback control.

Consistent bends and flanges with radius, grain direction, and K-factor consideration—ready for welding or assembly.

Precision tooling is the backbone of stamping. Our team ensures every die is engineered for performance, maintainability, and cost efficiency.

Trial runs validate the die before mass production. We provide sample submission and PPAP documentation to ensure customer confidence.

Regular sharpening, insert replacement, and preventive maintenance extend die life and ensure consistent part quality.

We stamp low-carbon, stainless, HSLA, and non-ferrous alloys for brackets, covers, clips, and deep-drawn parts.

Unsure which grade suits your part? Ask our engineers for a quick DFM recommendation.

Control corrosion, cosmetics, and assembly fit. We integrate finishing and value-added ops into the stamping flow.

Zinc (clear/yellow), Nickel, Tin—ideal for CRCA & HSLA parts.

Industrial coatings with proper pre-treatment for adhesion & salt-spray.

Type II/III for aluminum stampings; color options + wear resistance.

Through hardening / tempering for spring steels and wear parts.

Inline tapping, PEM/Gun inserts, clinch nuts—assembly-ready threads.

Spot/MIG/TIG, rivets, and jigs for repeatable sub-assemblies.

Tip: Define finish stack-ups early (coating thickness, masking, contact points) to avoid tolerance conflicts.

We follow APQP gates, submit PPAP documentation, and run gauge-driven inspections from incoming to final dispatch.

DFM review, risks, material & process selection, control strategy.

Process flow, PFMEA, control plan, gauge list, sampling plan.

Die build, tryout parts, capability study, correction loop.

Dimensional results, MSA, capability (Cp/Cpk), material certs, PSW.

Run-at-rate, SPC, periodic audits, gauge calibration, COA/COC.

| Level | Submission | When Used |

|---|---|---|

| 1 | PSW only | Low-risk, simple parts |

| 2 | PSW + limited data | Repeat builds w/ minor change |

| 3 | PSW + full package | New tooling / critical parts |

| 4 | As defined by customer | Custom requirements |

| 5 | Full + on-site review | High-risk programs |

Need a sample pack? Ask for Level 3 checklist.

Note: Gauge design and calibration records are maintained; traceability labels provided per shipment.

Production-ready stamping for high-volume parts with post-process support (finishes, threads, welding, assemblies).

Brackets, clips, shields, spring steel components, sensor housings.

EMI shields, battery tabs, terminals, enclosures, bus bars (Cu/Brass).

Guards, covers, stiffeners, cable trays, chassis with welded sub-assemblies.

Solar/electrical mounting hardware, bus bars, contact plates, housings.

Hinges, brackets, frames, panels; powder-coat or plated finishes ready.

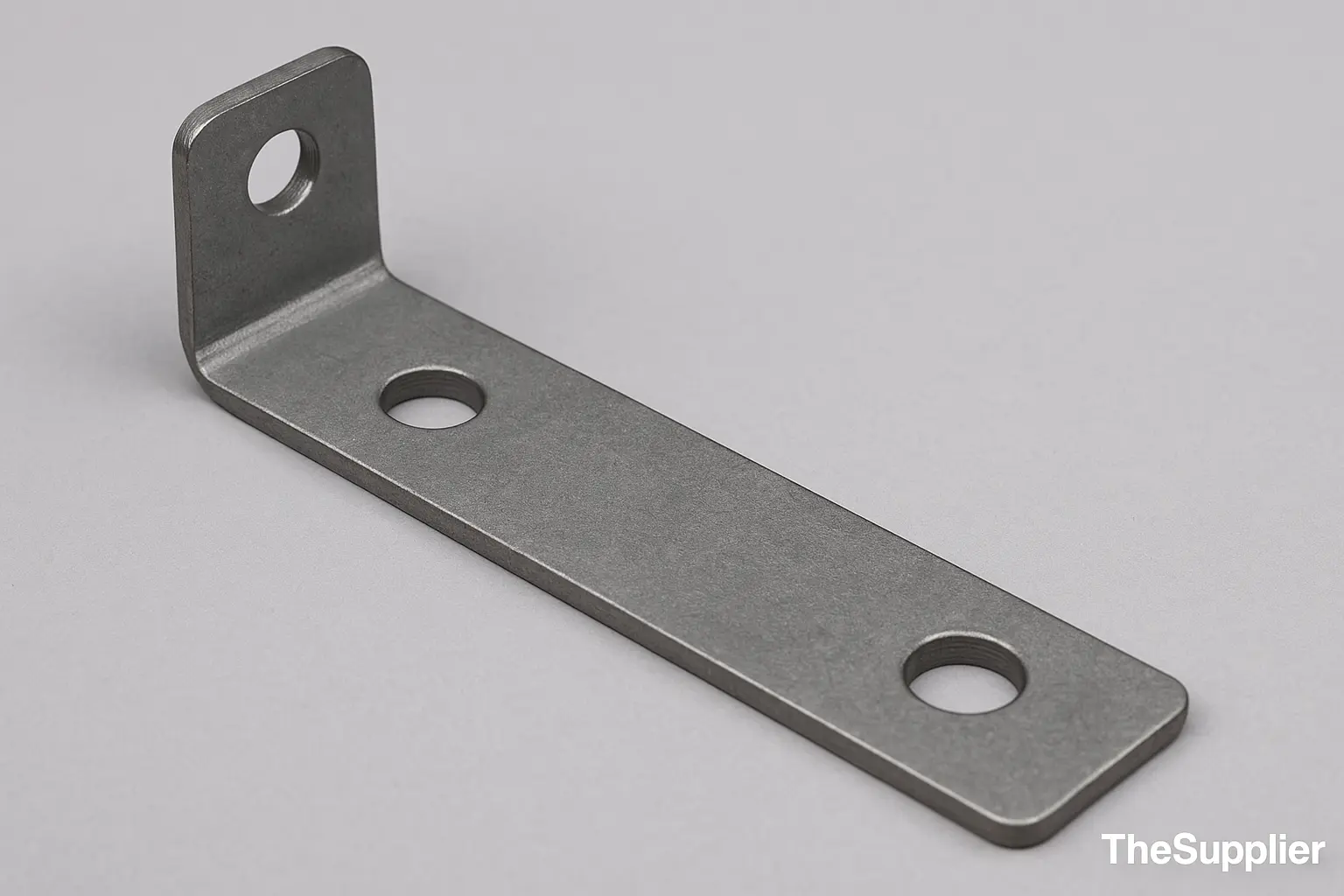

One representative production part from our network. The banner shows actual finish, edge quality, and hole accuracy from a live run.

This single part demonstrates real-world repeatability at speed: consistent edge condition, stable dimensions across long runs, and coatings that meet corrosion targets. The same approach scales from pilot batches to mass production without changing your drawing.

Tooling investment is upfront but pays back with lower cost per part in production. We keep timelines transparent from tryout to PPAP approval.

| Tooling Type | Cost Range (USD) | When Used |

|---|---|---|

| Simple Blanking / Piercing | $1,000 – $3,000 | Low volume, simple profiles |

| Forming / Bending Dies | $3,000 – $6,000 | Brackets, flanges, small formed parts |

| Progressive Dies | $8,000 – $25,000+ | High-volume, multi-operation parts |

| Deep Draw Dies | $10,000 – $30,000+ | Housings, cups, deep components |

* Actual cost depends on part complexity, cavity count, and finish requirements. Request a tooling cost estimate →

| Phase | Typical Duration | Notes |

|---|---|---|

| Tool Design & Build | 3 – 6 weeks | Depends on die complexity & tonnage |

| Tool Tryout | 1 week | Sample submission for review |

| PPAP Documentation | 1 – 2 weeks | Dimensional report, MSA, material certs |

| Mass Production Start | 1 – 2 weeks after approval | Run-at-rate validation included |

* Lead times can be shortened with idle-capacity allocation. Discuss fast-track options →

Access to idle capacity across vetted partners, tooling expertise, and in-house QC—so you get speed, consistency, and honest pricing.

We route jobs to presses with the right tonnage, feeders, and tooling support—reducing queue time and cost per part.

DFM, strip layout, and tolerance strategy up front. Fewer reworks, faster PPAP, longer die life.

Laser/soft tools for pilots, then progressive/transfer dies for scale—without changing your drawing or CTQs.

Gauge checks, capability sampling, and packaging QA—every lot verified.

Honest tooling bands and predictable lead times—no hidden markups.

Air for urgent PPAPs, optimized sea for production—export-ready packs.

Clear answers about processes, tolerances, tooling, and approvals.

Progressive die stamping combines multiple operations (blanking, piercing, forming) in one press stroke. Ideal for high volumes with repeatability and low cost per part.

Deep draw stretches a blank into a cavity using a punch and die. Depth depends on alloy, thickness, blank diameter, and reduction ratio; we typically target up to ~150 mm.

Typical outcomes: hole-to-hole ~±0.05 mm, hole-to-bend ~±0.10 mm, subject to alloy, thickness, and die design.

Yes — from DFM and strip layout to tryout and preventive maintenance (regrinds, inserts, spares).

We support APQP and provide PPAP (Levels 1–5) including PSW, dimensional reports, certs, and capability studies.

Upload drawings (STEP/DWG/PDF) with material and volume info. We respond in 48–72h with feasibility and lead times.