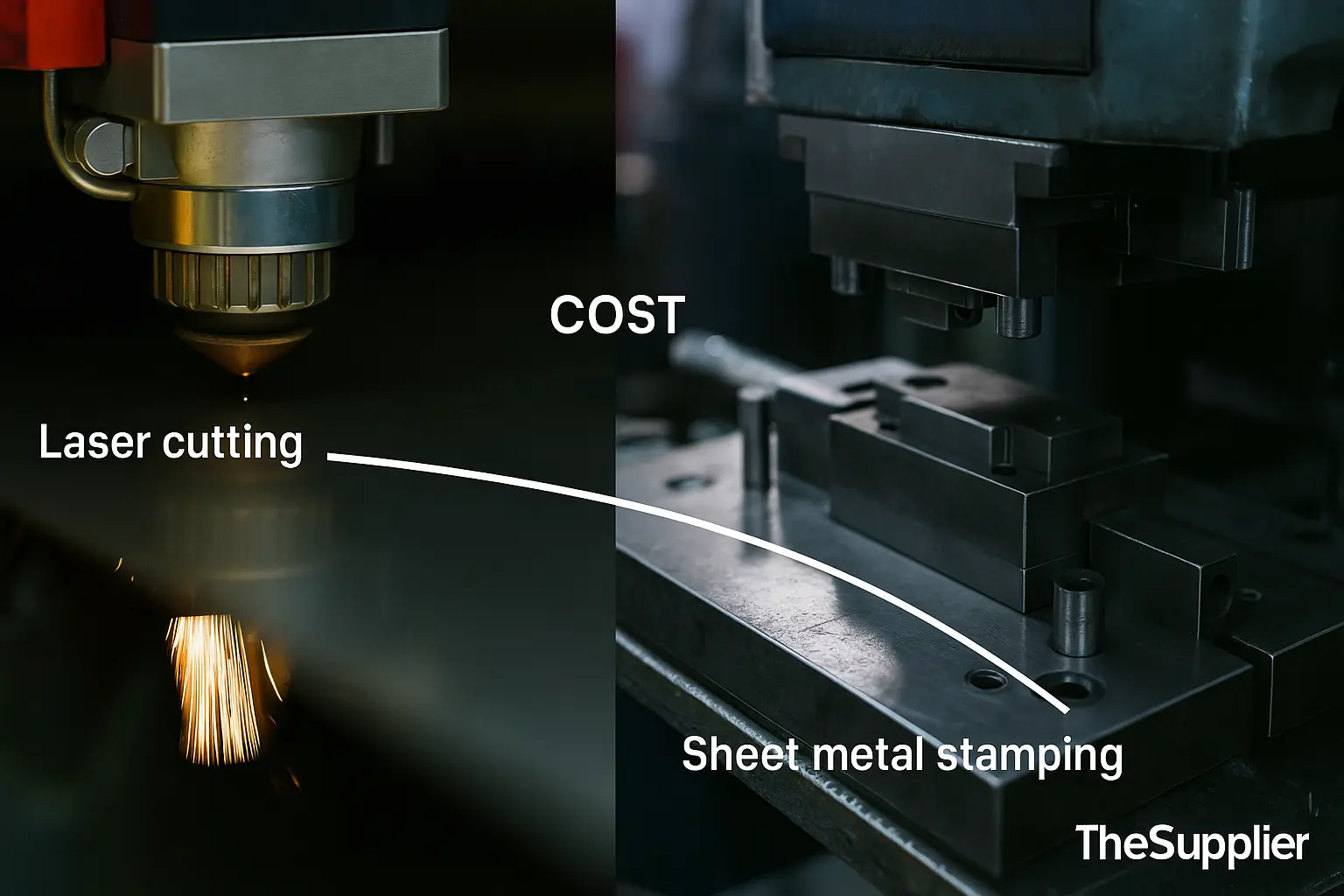

Sheet Metal Stamping vs Laser Cutting: Which Process Saves Cost?

A buyer-friendly comparison built for RFQs: break-even math, volume thresholds, quality risks, finishing impact, and sourcing tips from India.

Read more

- Clear cost model: when laser beats stamping — and when tooling wins.

- Fast selector for prototypes vs mass production.

- Hidden costs: redesign churn, fixturing, rework, finishing.

- Global sourcing lever: India for tooling, speed, QC.

No marketplace. TheSupplier is your managed procurement partner — we quote, build, inspect, and ship.

- Prototype / pilot or frequent design changes.

- Target qty per run: ~1–3,000 (size & gauge dependent).

- Tight deadlines: 24–72 hr start possible.

- Mixed SKUs, low repeatability, engineering in-progress.

- Stable design, repeating orders, long program life.

- High volumes — per-part seconds once die is built.

- In-die features: pierce, form, coin, extrude, tap.

- Lowest unit cost after tooling amortization.

- Start with laser → validate assembly, GD&T, finish.

- Freeze design → cut progressive or compound die.

- Move to stamping when annual qty clears break-even.

| Cost Element | Laser Cutting | Sheet Metal Stamping |

|---|---|---|

| Setup / NRE | No tooling. Program + nest → start fast. | Tooling upfront (blank, compound, progressive). |

| Per-Part Cost | Stable at low/medium qty. | Very low at high volumes; seconds per stroke. |

| Design Change Cost | Low — re-program & re-nest. | Medium/High — die rework or inserts. |

| Edge & Post-Process | Clean; minor burrs. HAZ on thick plates. | Coin/deburr in-die; consistent edges. |

| Lead Time to First Parts | Hours–days. | Days–weeks (die build) → then very fast/part. |

We run this on your real drawing, thickness, tolerances, and finishing plan.

- High repeat orders / annual schedules.

- Coil usage & better nesting → material yield.

- In-die operations replacing secondary processes.

- Laser: excellent profile accuracy; micro-burrs possible; tiny holes may need post-op.

- Stamping: coined edges; in-die extrusions/tapping possible.

- Laser: heat-affected zone on thick/highly conductive alloys.

- Stamping: forms without heat; springback tuned in try-out.

- Laser typically ±0.1–0.2 mm on thin sheet (process-dependent).

- Stamping tight & repeatable after die tuning; gauges control production.

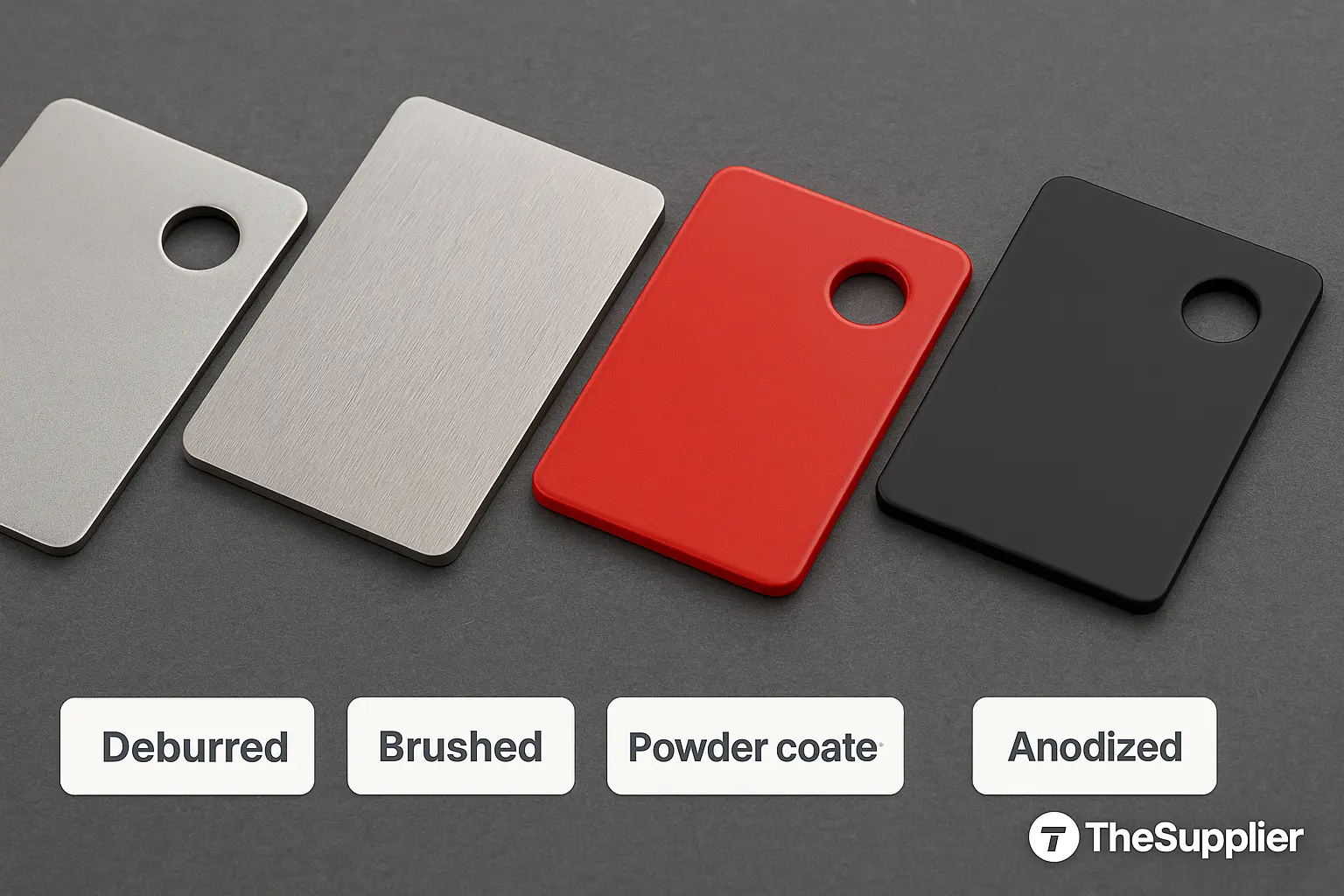

- Light deburr / edge break; media tumble for batch economy.

- Show faces: brush or powder; aluminum: anodize (II/III).

- Thin parts: use film to avoid rack/contact marks.

- In-die coin/deburr reduces secondary ops.

- Plate after forming; design drain/vent for liquids.

- Ra targets must consider forming lines & contact surfaces.

See: CNC Machining → “Finishes” and upcoming Surface Finishes in CNC Machining.

- Competitive die pricing & fast try-outs.

- Engineering support for progressive/compound tools.

- Laser parts in hours; stamping ramps after approval.

- PPAP/ISIR, traceability, photo/video evidence.

- Material yield + cycle time + finish + logistics considered together.

- Right-sized lot sizes reduce inventory cost.

- No tooling. Ideal for prototypes, ECOs, engineering churn.

- Fast turn; mix-SKU friendly.

- Good edge quality; minimal finishing on many parts.

- Very small holes may need post-op.

- HAZ on thick sections; flatness on large plates.

- Per-part cost steady — may not drop sharply with volume.

- Lowest unit cost at scale; seconds per stroke.

- In-die features replace multiple secondary ops.

- Highly repeatable quality after tool tuning.

- Tooling time & cost upfront; changes require rework.

- Not ideal for short-life or frequently changing designs.

- Requires volumes to amortize capex.

What quantity makes stamping cheaper than laser?

When tooling cost divided by the per-part delta (Laser unit − Stamping unit) is lower than your annual volume. We calculate the exact Q* on your drawing, thickness, and finish.

Can I start with laser and shift to stamping later?

Yes. Validate with laser parts first, then move to a progressive die once design stabilizes. We keep supplier continuity for smooth transfer.

Will laser edges affect powder coat or anodizing?

Edges are usually fine after a light deburr. For cosmetic faces, use media tumble + brush before finishing to keep Ra consistent.

How do you control stamping quality at scale?

Tool try-out with gauge plan, first-off approvals, SPC on critical features, and periodic CMM checks. ISIR/PPAP provided when required.

What if my design keeps changing?

Stay on laser until ECOs slow down. We’ll re-quote stamping when your forecast justifies it and lock the gauge plan.